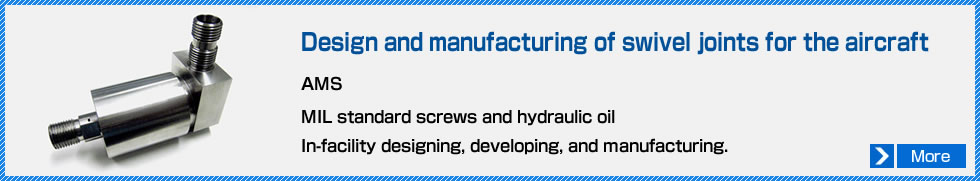

We manufacture and process a number of equipment parts related to aeronautics and space technology, for which precise dimensions and quality management are critical.

We are heavily involved with using titanium materials in the medical device industry, and we have a lot of experience with difficult-to-cut materials such as Inconel and CFRP.